The author Kathryn Sullivan-Butt is The Saddlefitter a Society of Master Saddlers Qualified fitter, ASFA fitter and an EA accredited coach. With formal saddle and saddlefit training in Australia, UK, US and Europe she is fortunate to have had the opportunity to train under (and quite frankly ask endless questions of) some of the industry’s most respected leaders. She fits full time in South-East Queensland.

VARIABLES OF SADDLE VALUE

There are two scents on earth that affects an equestrian like no other. The heady, earthy scent of a healthy horse combined with the subtle high notes of expensive leather. Ask most riders and they recognise the smell of quality leather indeed there is a reason that we loiter with deep breaths in front of the English leather bridles at our local saddlery. Inherently we know that the high quality vegetable tanned hides that take months to create are better than the chromed chemical smell of cheaper leathers. But leather aside there are many and variable factors that contribute to a quality saddle.

This series, starting with the science in saddles, will look at the different factors that begin to explain why $200.00 can in some instances purchase an entire saddle with all the mounts or ¦ purchase a pair of stirrup leathers alone.

So why the difference in price?

First we need to determine a reasonable expectation for the performance of our saddle. That is quite simply a device that will enable us to ride safely and at our best without causing the horse pain. A simple enough expectation but one that has had master saddlers (and more recently saddle fitters) look to all facets of saddle design and construction to optimise the safety and comfort for both horse and rider.

THE SCIENCE IN SADDLES

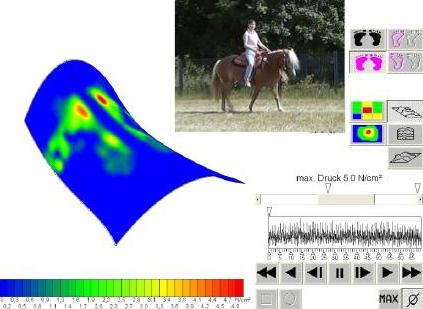

Increasingly science and technology is a key feature of quality saddle manufacturing from the materials used and their breaking strain to the pressure analysis results on the horses back.

Watching a master saddler bounce up and down on a newly constructed saddle tree (to illustrate the flexibility in a key area) is an image that sticks in the mind. Knowing that the design cost to get this one tree to its final stage of testing and development has likely cost over $100,000 dollars US indicates the dedication of this manufacturer to improving saddle construction. Design and manufacture can quite simply cost millions and we and our horses – reap the benefits.

Advances in design and materials such as heat malleable trees, cold press, new techniques to ensure saddle symmetry, air bags, state of the art memory foam panels and adjustable gullets are just some of these innovations. Having the confidence in a saddle company that they will thoroughly test these innovations is vital, but scientific testing and analysis, is an expensive undertaking that again is reflected in the price and quality of the saddle.

In the coming months we will examine other Variables of Value to why some saddles quite simply are more expensive to produce than others. These variables include but are not limited to

- Quality control and longevity the leather process explained, fittings and flocking

- Craftsmanship, environmental and social factors contributing to saddle quality/ price

- Follow up support training and education that will ensure best fitting and service for your saddle plus the contribution of saddle manufacturers to your sport

Finally with this month’s focus on technology the simple fact remains that quite simply some of the best aspects of a quality saddle are as true now as they were 100 years ago. It is the blend of science with master craftsmanship which is the true hallmark of quality ¦ but more on that next month.